Showroom

A Three Piece Can Making Machine is an industrial equipment utilized for automated production of cans. It operates on 380V, 50Hz, 3Phase electricity, with automatic functionality. Commonly applied in packaging industries, it forms metal sheets into cans efficiently. Typically comes with a 1-year warranty, ensuring reliability in production processes.

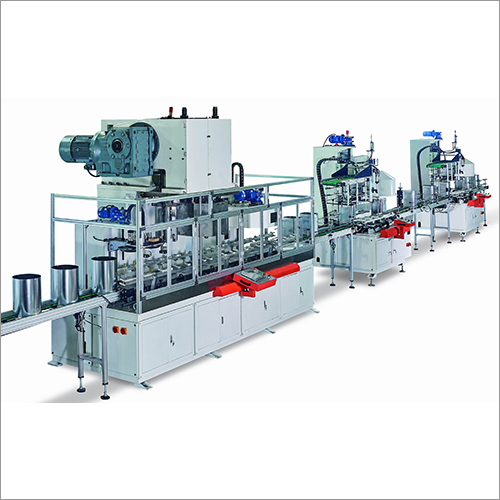

A Can Making Line Machines is utilized for numerous functions comprising welding seam, locating, expanding, flanging, and seaming. It operates at a capacity of 30CPM, suitable for 18L, 20L, and larger rectangular cans. With a connection height of 1000±10mm, it requires 380V/50Hz 3Phase electricity. Dimensions are 1700020003050mm, weighing 31000kg.

A Can Ends Making Machine is an industrial device mostly utilzed for automated production of can ends. It operates on 380V, 50Hz, 3Phase electricity with automatic functionality. Utilized in packaging industries, it manufactures can ends efficiently. Typically comes with a 12-month warranty, guaranteeing reliability and consistency in can end production.

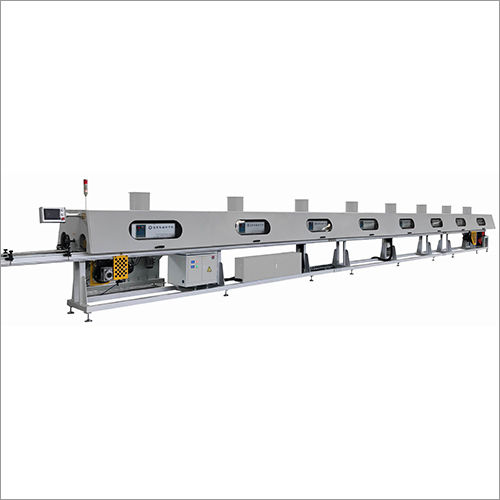

An Induction Curing Oven is an industrial electric oven made of steel. It's used for curing processes, providing precise temperature control. With a voltage range of 220-440V, it has a capacity of 100-150CPM to 500-600CPM, ensuring efficient curing in various industrial applications.

A Powder Coating Machine is used for applying PET epoxy resin powder coatings. It operates at a max speed of 80m/min, with a capacity of 600 cans/min. Suitable for can diameters from D52 to D400mm, with coating widths of 6-16mm. Requires single-phase AC22V electricity and compressed air at 0.6MPa.

A Can Body Welder Machine is engineered to be utilized for welding can bodies. It offers welding speeds ranging from 28m/min to 66m/min. Capable of handling capacities from 60cpm to 500cpm, it guarantees efficient production across varied speeds to meet various manufacturing requirements.

A DRD Can Making Machine is designed for manufacturing DRD (Draw Redraw Double) cans. With a pressure of 120MT and a speed of 200SPM, it processes sheets up to 1001100mm and 0.4mm thickness. It operates on 25kW power, 380V/50Hz/3Phase electricity, with dimensions of 30001500*2900mm and a weight of 11000kg.

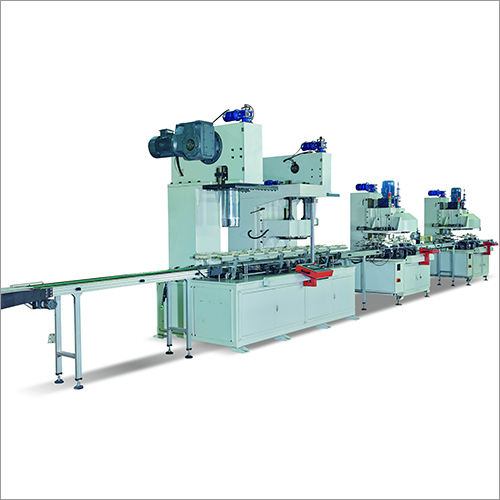

A Conical Pail Line Machine is utilized for expanding, flanging, beading, and seaming conical pails. It operates at a capacity of 30CPM, accommodating can diameters of D200-300mm and heights of 180-500mm. With a connection height of 1000±10mm, it requires 30kW power, 380V 50Hz 3Phase electricity. Dimensions: 1600019003050mm, Weight: 15000kg.

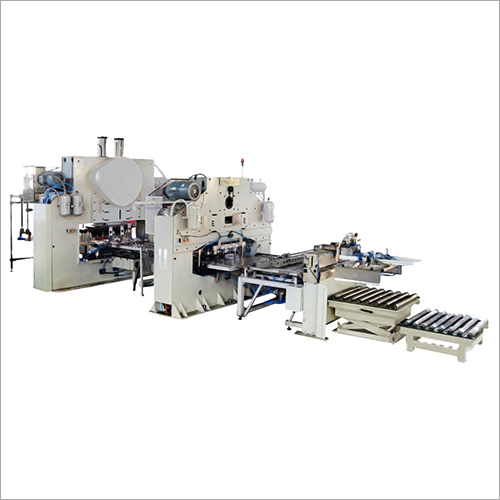

An EOE (Easy Open End) Making Line is a production system for manufacturing can ends. With press tonnage of 75-125MT and max speed of 650SPM, it offers 1-4 lane output configuration. Capable of producing up to 2500 ends per minute, it accommodates diameters ranging from 202mm to 603mm. Powered by 36-48KW.